Introduction

The prevailing economic model for much of modern history has been linear: resources are extracted, manufactured into products, used, and then discarded as waste – a 'take-make-waste' system. This model relies heavily on the consumption of finite resources and generates vast quantities of waste, estimated at over 100 billion tonnes of materials consumed globally each year, with more than 90% ultimately wasted.

A significant portion of this waste stream consists of organic materials, such as food scraps, which constitute 24. 1% of municipal solid waste (MSW) landfilled in the U. S. , rising to 51. 4% when yard trimmings, wood, and paper are included.

Persistent materials like conventional plastics, derived largely from fossil fuels, further exacerbate environmental pollution and resource depletion. If you want to explore this connection in-depth, here’s how biodegradable trash fits into a sustainable lifestyle.

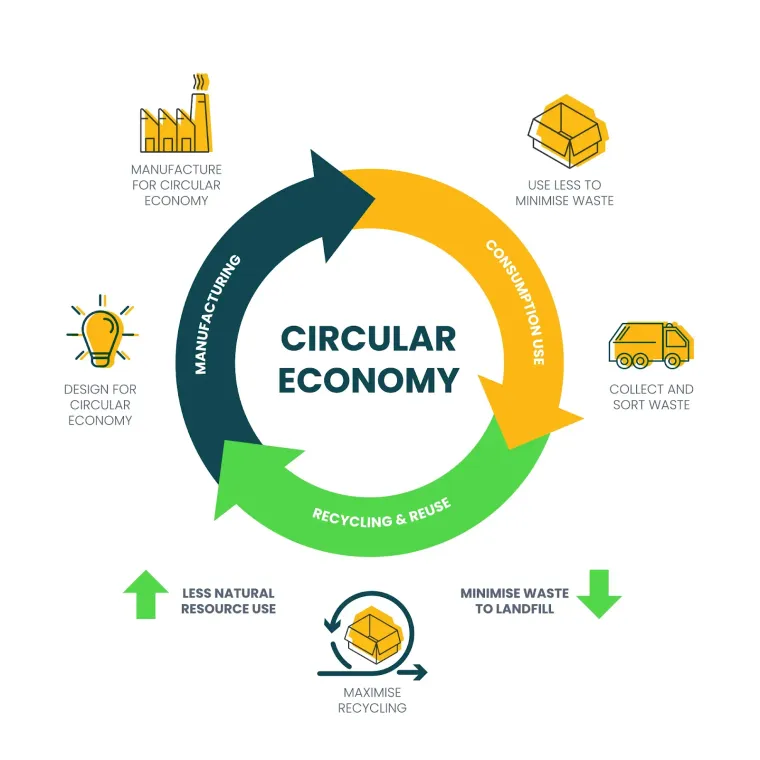

In response to the evident unsustainability of this linear approach, the concept of a circular economy (CE) has gained prominence. The circular economy offers a systemic alternative designed to benefit businesses, society, and the environment by fundamentally rethinking how we produce and consume goods.

As defined by leading organizations like the Ellen MacArthur Foundation (EMF), the OECD, and the United Nations, the CE aims to gradually decouple economic growth from the consumption of finite resources. This is achieved through adherence to three core principles, driven by design: 1) eliminate waste and pollution; 2) circulate products and materials at their highest value; and 3) regenerate natural systems.

This framework represents not merely an improvement in waste management but a paradigm shift towards a restorative and regenerative economic model. Such a shift necessitates transforming the entire system, from resource management and product design to end-of-life pathways, moving beyond incremental improvements to established linear practices.

Within this transformative vision, the role of biodegradable materials – encompassing both naturally occurring organic waste and manufactured products designed to break down – requires careful examination. Biodegradability appears, at first glance, to align well with the CE goal of eliminating persistent waste. However, its actual contribution to circularity is complex and contingent.

The central question this report addresses is: How do biodegradable materials connect with the principles and practicalities of a circular economy? Are they key enablers of resource cycling and regeneration, or do they present unique challenges that must be carefully managed? This analysis will critically evaluate the potential and limitations of biodegradable materials within the circular economy framework, moving beyond simplistic assumptions to provide a nuanced understanding.

The connection between biodegradability and the CE's imperative to reduce reliance on finite resources is particularly important; while biodegradability addresses waste persistence, the origin and lifecycle impacts of these materials must also be considered.

Decoding the Terminology

Navigating the landscape of sustainable materials requires a clear understanding of the terminology used, particularly the often-confused terms "biodegradable," "compostable," and "bio-based. " Misunderstanding these terms hinders effective waste management and the transition towards a circular economy.

Defining "Biodegradable"

At its core, "biodegradable" refers to the ability of a substance to be broken down by the action of naturally occurring microorganisms, such as bacteria and fungi, into simpler components like carbon dioxide (CO2), water, methane (CH4) (in the absence of oxygen), biomass, and mineral salts.

This natural process applies to many organic materials like food scraps, paper, cotton, and wood. For a deeper understanding of biodegradation mechanisms, explore what makes a material biodegradable: key characteristics.

However, the general term "biodegradable" lacks specificity regarding the conditions and timeframe required for decomposition. The rate and extent of biodegradation are highly dependent on the surrounding environment, including the medium (e. g. , soil, water, compost), temperature, moisture levels, oxygen availability, and the presence of specific microbial communities.

Consequently, a material that biodegrades readily in one environment (like an industrial composter) might persist for significantly longer, or fragment incompletely, in another (like the ocean or a landfill).

Recognizing this ambiguity, regulatory bodies have attempted to provide more context. Certain definitions under the U. S. Environmental Protection Agency (EPA), for instance, specify performance criteria for particular substances, such as yielding 60% of theoretical maximum CO2 within 28 days under specific aerobic aquatic biodegradation test conditions for biocidal substances.

Furthermore, the U. S. Federal Trade Commission's (FTC) "Green Guides" state that making an unqualified "degradable" claim for products typically entering the solid waste stream (like landfills) is deceptive if the item does not completely decompose within one year after customary disposal.

This highlights that simply labeling a product "biodegradable" without qualification can be misleading, as standard disposal environments like landfills often lack the conditions (e. g. , oxygen, microbes) necessary for rapid and complete breakdown.

The inherent vagueness of the term, unless rigorously qualified by specific conditions and timeframes according to standardized tests, creates potential for "greenwashing," where an environmental benefit is implied but may not be realized in practice.

Clarifying Crucial Differences

Understanding the distinctions between related terms is vital:

Biodegradable vs. Compostable

Compostability is a specific, more rigorous form of biodegradability. A material is considered "compostable" if it can biodegrade under specific, controlled conditions (typically in a composting facility) within a defined timeframe, breaking down into CO2, water, inorganic compounds, and biomass (compost) without leaving harmful residues.

Therefore, all compostable materials are biodegradable under those specific composting conditions, but the reverse is not true; many biodegradable materials will not meet the criteria for compostability. For clarity, this guide on the difference between biodegradable and compostable waste offers a detailed breakdown.

Industrial vs. Home Compostable

Compostable materials are further distinguished by the environment they are designed for. Industrially compostable plastics require the conditions found in commercial or industrial composting facilities, characterized by elevated temperatures (typically 50-60°C or higher), controlled moisture, and specific microbial populations.

Home compostable plastics are designed to break down in the lower temperatures (ambient) and less controlled conditions of a well-managed home compost bin. Products certified only for industrial composting may not fully decompose in a home compost setting.

Bio-based vs. Biodegradable/Compostable

The term "bio-based" refers exclusively to the origin of the material's feedstock. A bio-based product is derived wholly or partially from renewable biological resources, such as corn starch, sugarcane, algae, or agricultural waste, rather than fossil fuels. Critically, "bio-based" does not imply anything about the material's end-of-life fate.

Bio-based plastics can be designed to be non-biodegradable and recyclable within conventional streams (e. g. , bio-polyethylene (bio-PE), bio-polyethylene terephthalate (bio-PET), often called 'drop-ins'), or they can be designed to be biodegradable and/or compostable (e. g. , polylactic acid (PLA), polyhydroxyalkanoates (PHAs)). Conversely, some biodegradable plastics, like polybutylene adipate terephthalate (PBAT), are derived from fossil resources.

The Importance of Standards and Conditions

To lend credibility and clarity to claims, standardized testing protocols and certifications are essential. Key standards include ASTM D6400 in the United States and EN 13432 in Europe, which define the criteria for plastics to be considered compostable in industrial facilities.

These standards typically require specific levels of biodegradation (conversion to CO2) within a set timeframe (e. g. , 180 days), disintegration (breaking into small fragments), and absence of negative effects on the composting process or the final compost quality (e. g. , low heavy metals, no ecotoxicity).

Standards for home compostability (e. g. , 'OK compost HOME') exist but are less common and require degradation under less controlled, lower-temperature conditions. Currently, there are no widely accepted ASTM standard test methods for home composting in the USor general standards for biodegradation in specific natural environments like soil or marine water, due to the inherent variability of these conditions.

This gap between standardized test conditions and real-world environments is a significant challenge, as the actual fate of a biodegradable or compostable product depends critically on whether its disposal pathway matches the specific conditions it was designed and tested for. Mismatches can lead to persistence, fragmentation, or other unintended consequences, negating the intended environmental benefit.

Table Clarifying Sustainable Material Terminology

| Term | Definition | Primary Focus | Source Material | Typical End Products (under ideal conditions) | Key Standards/Conditions | Link to Circularity |

|---|---|---|---|---|---|---|

| Biodegradable (General) | Capable of being broken down by microorganisms into natural substances. | End-of-Life | Fossil or Bio-based | CO2, H2O, Methane (anaerobic), Biomass | Highly variable; depends on material & environment. Unqualified claims often lack specific standards/timeframes. | Potential fit in biological cycle if conditions met & non-toxic. Vague claims can be misleading & hinder proper sorting. |

| Compostable (Industrial) | Biodegrades under controlled industrial composting conditions (high temp, moisture, microbes) within a specific timeframe. | End-of-Life | Fossil or Bio-based | CO2, H2O, Biomass (Compost) | Specific standards (e.g., ASTM D6400 | Fits biological cycle if collected & processed in appropriate industrial facilities. Creates valuable soil amendment. |

| Compostable (Home) | Biodegrades under home composting conditions (lower temp, less controlled) within a specific timeframe. | End-of-Life | Fossil or Bio-based | CO2, H2O, Biomass (Compost) | Specific standards exist (e.g., OK compost HOME | Fits biological cycle if composted correctly at home. Increases accessibility but relies on consumer action & knowledge. |

| Bio-based | Derived wholly or partially from renewable biological resources (plants, algae, etc.). | Origin | Bio-based (Renewable) | Varies (can be non-biodegradable) | Refers to % bio-based content (e.g., ASTM D6866 | Reduces reliance on finite fossil fuels (if sourced sustainably). End-of-life depends on material type (technical or biological cycle). |

| Conventional Plastic | Typically derived from fossil fuels (petroleum, natural gas). | Origin/Properties | Fossil-based (Non-renewable) | Persistent material; fragments into microplastics | Designed for durability/performance. Recyclable (some types), but often landfilled/incinerated. | Primarily fits technical cycle (recycling). Linear model leads to resource depletion & persistent pollution. |

The Circular Economy

The circular economy (CE) provides a comprehensive framework for rethinking our relationship with resources and materials. It moves beyond the linear 'take-make-waste' model towards a system designed for longevity, reuse, and regeneration.

Core Principles Revisited

As established by proponents like the Ellen MacArthur Foundation (EMF), the CE is guided by three interconnected principles, driven by design:

Eliminate Waste and Pollution

This principle tackles the negative outputs of the linear system at their source. It involves designing products and systems to prevent waste generation and pollution from the outset, rather than managing them after they occur.

Circulate Products and Materials (at their highest value)

This focuses on keeping resources in use for as long as possible. It prioritizes strategies that maintain the embedded value (energy, labor, materials) within products and components through processes like maintenance, reuse, refurbishment, and remanufacturing. Recycling, which breaks materials down, is considered a lower-value loop, employed when higher-value options are no longer feasible.

Regenerate Nature

This principle aims to actively improve natural systems. It involves shifting towards practices that enhance ecosystems, such as returning valuable nutrients to the soil through biological cycles, promoting biodiversity, and transitioning to renewable energy and materials.

The overarching goal is to decouple economic activity from the consumption of finite resources, building a resilient system beneficial for the economy, society, and the environment.

Biological and Technical Cycles

A central concept in the EMF's visualization of the circular economy (the 'butterfly diagram') is the distinction between two fundamental material flows

The Biological Cycle

This cycle encompasses materials that can safely re-enter the biosphere after use, where they decompose naturally and return valuable nutrients to the environment, thus regenerating natural capital.

This includes materials like food waste, garden trimmings, paper, wood, natural fibers, and specifically designed biodegradable/compostable materials. To dive deeper into their decomposition characteristics, check out the spectrum of biodegradability: from rapid to gradual decomposition.

Processes like composting and anaerobic digestion facilitate this cycle. The emphasis within the CE framework is not merely on disposal but on actively returning value – nutrients and carbon – to support soil health and ecosystem regeneration, directly aligning with the "Regenerate Nature" principle.

The Technical Cycle

This cycle deals with materials that cannot safely return to the biosphere, primarily finite materials like metals, minerals, and conventional plastics derived from fossil fuels. These materials must be kept circulating within the economy at their highest possible value for as long as possible. Strategies within this cycle, ordered from highest to lowest value preservation, include maintenance, reuse, refurbishment, remanufacturing, and finally, recycling.

Biodegradable materials naturally fit within the biological cycle. Organic waste forms the primary input, while manufactured biodegradable or compostable products are designed to follow this pathway at their end-of-life, ideally returning resources to the soil.

However, the existence of materials that blur the lines – such as bio-based plastics designed for the technical cycle (recycling)or fossil-based plastics designed for the biological cycle (composting)– underscores the critical need for clear design intent, unambiguous labeling, and effective sorting systems.

Without these, materials risk ending up in the wrong cycle, leading to contamination and undermining the circularity of both streams. Ensuring materials follow their intended pathway based on end-of-life design, not just origin, is crucial.

The Waste Hierarchy within Circularity

The well-established waste hierarchy (typically ranked as Prevention > Reuse > Recycling > Recovery > Disposal) provides a prioritization framework that aligns closely with circular economy principles. The CE reinforces this hierarchy, strongly emphasizing upstream solutions like waste prevention through design (eliminating unnecessary materials) and extending product life through reuse and repair models.

Within this hierarchy, processes for biodegradable materials like composting and anaerobic digestion fall under 'Organic Recycling' or 'Recovery'. While vastly preferable to landfilling, these biological processes are generally considered lower-value loops than prevention, reuse, refurbishment, or even the recycling of technical materials, because they involve breaking down the material structure.

Therefore, in a truly circular system, biodegradability should be pursued primarily when higher-value options like reduction, reuse, or technical recycling are not feasible or practical. Relying heavily on compostable single-use items without first optimizing reduction and reuse could inadvertently perpetuate linear consumption patterns, even if the materials themselves are biodegradable.

Pathways for Biodegradable Waste in a Circular System

The circular economy provides specific pathways for managing biodegradable materials, transforming them from potential waste streams into valuable resources. The two primary methods are composting and anaerobic digestion, both central to closing the biological nutrient loop.

Composting: Aerobic Decomposition for Nutrient Recovery

Composting is a managed biological process that utilizes microorganisms (bacteria, fungi) to decompose organic materials in the presence of oxygen (aerobically). Common feedstocks include food scraps, yard trimmings, paper products, and certain certified compostable materials.

For equipment suggestions, here’s a helpful guide on the optimal composting bins for biodegradable waste.

Effective aerobic composting relies on maintaining specific conditions within the compost pile or system:

Balanced Nutrients

A crucial factor is the carbon-to-nitrogen (C:N) ratio of the input materials. Microbes use carbon for energy and nitrogen for growth and reproduction. Explore more in biodegradable waste: what can and cannot be composted.

An optimal C:N ratio, typically between 25:1 and 30:1 by weight, ensures efficient decomposition. Materials rich in carbon ("browns" like dry leaves, wood chips) must be balanced with nitrogen-rich materials ("greens" like food scraps, grass clippings). Too high a C:N ratio slows decomposition, while too low a ratio can lead to nitrogen loss as ammonia gas and potential odors.

Moisture Content

Microorganisms require adequate moisture for their metabolic processes. The ideal moisture range is typically 40-65%. Below 40%, microbial activity slows significantly; above 65%, water can fill air pores, leading to anaerobic conditions and odors.

Oxygen Supply (Aeration)

Aerobic microbes require oxygen. Sufficient aeration, achieved through pile structure (particle size, porosity) and/or turning, is necessary. Oxygen concentrations within the pile should ideally remain above 5%.

Particle Size

Smaller particles offer more surface area for microbial action but can impede airflow if too fine. A range of particle sizes, often averaging 1/8 to 2 inches (approx. 3mm to 50mm), is generally preferred.

Temperature

Microbial activity generates heat. Temperatures typically rise into the thermophilic range (above 105°F or 41°C). Maintaining temperatures between 131°F and 160°F (55°C and 71°C) for a specific duration (e. g. , several days, depending on the method) is crucial for rapid decomposition and the destruction of pathogens, weed seeds, and fly larvae.

The primary output of composting is compost, a stable, humus-like material rich in organic matter and nutrients. Applying compost improves soil structure, aeration, water infiltration and retention, and provides essential plant nutrients, reducing the need for synthetic fertilizers.

Furthermore, incorporating stable carbon from compost into soils contributes to carbon sequestration, helping to mitigate climate change. By returning nutrients and carbon to the soil, composting directly fulfills the CE principle of regenerating natural systems.

Anaerobic Digestion (AD)

Anaerobic digestion is another biological process, but it occurs in the absence of oxygen. Specialized microorganisms break down organic feedstocks within sealed reactors or digesters.

Suitable feedstocks include animal manures, food waste, fats, oils, and greases (FOGs), wastewater solids (biosolids), and industrial organic residues. Co-digestion, the simultaneous processing of multiple feedstocks, can enhance biogas production and process stability. You may also find this article useful: how worm composting helps break down biodegradable trash.

The AD process involves four key biochemical stages:

Hydrolysis

Complex organic polymers (carbohydrates, proteins, fats) are broken down into simpler soluble molecules (sugars, amino acids, fatty acids) by hydrolytic bacteria.

Acidogenesis

Acidogenic bacteria ferment these simple molecules into volatile fatty acids (VFAs), alcohols, ammonia, CO2, and hydrogen.

Acetogenesis

Acetogenic bacteria convert the VFAs and alcohols into acetic acid, CO2, and hydrogen.

Methanogenesis

Methanogenic archaea convert acetic acid, hydrogen, and CO2 into methane (CH4) and CO2, the main components of biogas.

AD produces two primary outputs:

Biogas

A mixture primarily composed of methane (50-75%) and carbon dioxide, with trace amounts of other gases like hydrogen sulfide (H2S) and water vapor. Biogas is a renewable energy source that can be combusted to generate heat and/or electricity (often in combined heat and power - CHP systems), used as fuel in boilers, or upgraded to Renewable Natural Gas (RNG) by removing CO2 and impurities. RNG can be injected into natural gas pipelines or used as vehicle fuel.

Digestate

The residual material remaining after digestion, consisting of undigested organic matter, microbial biomass, and inorganic components. Digestate is rich in nutrients (nitrogen, phosphorus, potassium) and is typically separated into liquid and solid fractions. Both fractions can be used as valuable fertilizers and soil amendments, returning nutrients to agricultural land. Solids can sometimes also be used for animal bedding or as feedstock for other bio-based products.

AD offers multiple benefits aligned with the CE: it diverts organic waste from landfills (reducing methane emissions), generates renewable energy (offsetting fossil fuel use), reduces pathogens and odors compared to raw manure storage, and recovers valuable nutrients for agriculture, closing the nutrient loop. It supports both the 'Circulate Products and Materials' (nutrient recovery) and 'Regenerate Nature' (renewable energy, soil health) principles.

Transforming 'Waste' into Resources

Both composting and AD exemplify a core tenet of the circular economy: viewing discarded materials not as waste to be disposed of, but as feedstocks for creating new value. They transform organic streams into soil-enhancing products and renewable energy, contributing to resource efficiency and environmental protection.

While distinct in their primary outputs (compost vs. biogas + digestate), these pathways can be complementary within a regional waste management system, chosen based on local needs and feedstock availability. However, the successful circularity of both pathways hinges on the quality of the outputs.

Contamination of feedstocks with persistent materials like conventional plastics, heavy metals, or failure to eliminate pathogens during processing can render the resulting compost or digestate unsuitable for beneficial use, potentially causing environmental harm and breaking the intended circular loop. Therefore, ensuring clean inputs and effective process control is paramount for realizing the regenerative potential of these biological cycles.

Challenges and Realities

Despite the potential alignment with circular economy principles, the widespread adoption and effective management of biodegradable materials face significant practical challenges and limitations. These materials, particularly manufactured biodegradable plastics, are far from a simple solution to waste management issues.

The Landfill Issue: Methane and Persistence

A primary driver for diverting organic waste is the problem it creates in landfills. Landfills are generally designed for containment, creating anaerobic (oxygen-deprived) conditions that inhibit aerobic decomposition. When biodegradable organic matter like food scraps decomposes anaerobically, it generates methane (CH4), a greenhouse gas significantly more potent than CO2 in the short term. Food waste is identified as a major contributor to landfill methane emissions.

Manufactured biodegradable plastics often fare poorly in landfill environments. Due to the lack of sufficient oxygen, moisture, and appropriate microbial populations, many biodegradable and even compostable plastics fail to break down significantly or within meaningful timeframes.

While some research suggests materials like PLA might generate minimal methane under typical moderate landfill temperatures due to slow hydrolysis, other studies or conditions might indicate potential for gas generation, particularly over extended periods or in actively managed "bioreactor" landfills.

The general consensus, however, is that landfill disposal negates the intended environmental benefit of biodegradation for these plastics. Here's a breakdown of how biodegradable trash breaks down compared to regular waste.

Microplastic Concerns

The incomplete degradation of plastic materials, including biodegradable and compostable types when exposed to conditions outside their design parameters (e. g. , in soil, water, or even poorly managed compost), can lead to fragmentation into smaller pieces known as microplastics (typically <5mm).

Oxo-degradable plastics, which contain additives to accelerate fragmentation through oxidation, are particularly problematic in this regard, as their primary degradation pathway involves creating microplastics. If you're concerned about greenwashing, check out debunking myths about biodegradable trash.

These microplastics are persistent pollutants found ubiquitously in oceans, freshwater, soil, and air. Due to their small size and large surface area, they can adsorb and transport other environmental pollutants and potentially leach additives, posing risks to ecosystems and potentially human health through ingestion or inhalation.

Systemic Hurdles

A fundamental barrier to the effective management of biodegradable materials, especially compostable packaging, is the lack of adequate infrastructure. This includes:

Collection

Insufficient access to separate collection streams for organic waste and compostable materials at the residential and commercial levels.

Processing

A shortage of industrial composting facilities or anaerobic digestion plants capable of accepting and effectively processing these materials, particularly mixed food waste and compostable packaging. Only a small percentage of US composting facilities currently accept food-contact compostable packaging.

Sorting

Difficulty and cost associated with sorting biodegradable/compostable plastics from other waste streams, especially conventional plastics.

Investment in this necessary infrastructure is often hindered by financial constraints, particularly in developing regions, and the perceived lack of profitability without supportive policies.

Communication Breakdown

Significant confusion exists among consumers regarding the meaning of terms like "biodegradable," "compostable," and "bio-based," and the correct disposal methods for products bearing these labels. Studies show that up to half of consumers struggle to differentiate between "biodegradable" and "compostable". Inconsistent, unclear, or ambiguous labeling exacerbates this problem.

For example, the phrase "made from plants" can apply to both recyclable bio-based plastics and compostable plastics, leading to incorrect disposal decisions. This confusion results in improper sorting – compostables ending up in recycling bins or landfills, and non-compostables contaminating organic streams – thereby undermining the effectiveness of both recycling and composting systems.

Contamination Issues

The mis-sorting driven by confusion and inadequate infrastructure leads directly to contamination problems:

Recycling Stream Contamination

Biodegradable and compostable plastics (like PLA) entering the recycling stream for conventional plastics (like PET or PE) act as contaminants. They have different melting points and properties, reducing the quality, processability, and market value of the recycled conventional plastic. Separating them effectively is currently challenging and costly.

Organic Stream Contamination

Conversely, conventional plastics mistakenly placed in organic waste collection bins contaminate the feedstock for composting or AD. These plastics do not break down and persist in the final compost or digestate, reducing its quality, potentially hindering its use in agriculture, and contributing to microplastic pollution in soils.

The Performance Gap: Standards vs. Reality

As previously noted, certifications for compostability (e. g. , ASTM D6400, EN 13432) are based on performance in specific, controlled industrial composting environments. These optimized conditions (high temperature, controlled moisture, active microbes) are often not replicated in real-world disposal scenarios such as home compost piles, soil, marine environments, or landfills.

This creates a significant performance gap: a product certified as "compostable" may fail to break down effectively or within the expected timeframe if it ends up in an environment different from the one specified in the standard. This discrepancy undermines the reliability of biodegradability claims and contributes to environmental persistence.

Lifecycle Considerations (LCA)

A holistic view requires assessing the entire lifecycle environmental impacts of biodegradable materials compared to conventional ones, using methodologies like Life Cycle Assessment (LCA).

Potential Benefits

Bio-based plastics can offer advantages, particularly in reduced greenhouse gas (GHG) emissions and lower non-renewable energy use (NREU) during production compared to their fossil-based counterparts, especially when derived from second-generation feedstocks (e. g. , waste biomass).

Some studies show PLA production uses significantly less energy and releases fewer GHGs during decomposition in landfills compared to certain conventional plastics. See more about the environmental benefits of biodegradable trash and the lower carbon footprint of biodegradable materials.

Potential Drawbacks

The agricultural production of biomass feedstocks (especially first-generation, like corn or sugarcane) can have significant environmental impacts, including land use change (potentially deforestation), water consumption, fertilizer and pesticide use leading to eutrophication (excess nutrients in water bodies) and acidification, and impacts on biodiversity.

End-of-Life Dominance

The end-of-life management pathway (e. g. , composting, AD, recycling, incineration, landfill) heavily influences the overall LCA results. If biodegradable products are not managed correctly (e. g. , landfilled instead of composted), their potential upstream benefits can be negated, and they may perform worse overall than conventional, recyclable alternatives.

These multifaceted challenges are deeply interconnected. Gaps in collection and processing infrastructure make it difficult for consumers to dispose of materials correctly, even if they understand the labels. Confusing labels lead to contamination, which devalues recycled materials and compost.

The performance gap means that even well-intentioned disposal into the wrong environment leads to persistence and potential microplastic pollution. This complex interplay creates significant hurdles for integrating biodegradable materials effectively into a circular economy.

Furthermore, an overemphasis on biodegradability as an end-of-pipe solution risks diverting attention and investment from higher-priority circular strategies like waste prevention (designing out waste) and reuse models, potentially locking in single-use consumption patterns, albeit with different materials.

Optimizing the Role of Biodegradables

To harness the potential benefits of biodegradable materials while mitigating their drawbacks, a strategic and systemic approach is required, integrating them thoughtfully within the broader circular economy framework.

Strategic Applications

The use of manufactured biodegradable and compostable materials should be targeted towards applications where they offer distinct advantages over conventional materials and align with feasible end-of-life pathways. Key niche applications include:

Items Contaminated with Food Waste

Packaging and serviceware likely to be heavily soiled with food residues (e. g. , coffee pods, tea bags, food wrappers, plates, cutlery used in closed systems like festivals or canteens) are strong candidates for compostable materials. Here’s a practical look at the science behind biodegradable food containers.

Composting allows both the packaging and food scraps to be processed together, diverting food waste from landfills and avoiding contamination issues inherent in recycling food-soiled conventional packaging. Compostable bags used to line kitchen caddies also facilitate cleaner collection of food scraps for composting or AD.

Agricultural Applications

Biodegradable mulch films that break down in the soil after use can reduce plastic waste accumulation in fields and the labor associated with removing conventional plastic films. Standards exist for assessing biodegradability in soil for these applications.

Applications with High Environmental Loss Rates

In specific cases where products are likely to be lost to the environment and difficult to retrieve (e. g. , certain fishing gear components), materials designed to biodegrade in relevant environments (e. g. , marine) could theoretically reduce long-term persistence. However, robust standards and proven performance in these complex environments are still largely lacking.

Conversely, biodegradable materials should generally be avoided where durable, reusable alternatives are practical, or where established and effective recycling systems exist for conventional materials.

The Role of Policy and Regulation

A supportive and clear policy landscape is fundamental for the successful integration of biodegradable materials into the circular economy. Key policy levers include:

Standards and Labeling

Implementing clear, consistent, scientifically robust, and legally enforceable standards and labeling requirements is crucial. This includes differentiating clearly between biodegradable, industrially compostable, home compostable, and bio-based materials, specifying the required disposal environment, and using unambiguous language and symbols. Harmonization of standards across jurisdictions reduces confusion.

Marketing Claims

Rigorous enforcement against misleading or unsubstantiated environmental claims (greenwashing) is necessary, utilizing frameworks like the FTC's Green Guides. Claims must be backed by credible scientific evidence relevant to real-world conditions. To better understand the limitations of labeling, this article explores the truth about biodegradable plastic bags – are they really eco-friendly?

Waste Management Mandates

Policies mandating the diversion of organic waste from landfills are powerful drivers. Examples include the EU Landfill Directive setting targets for reducing biodegradable municipal waste landfilling, and state/municipal organic waste bans in North America (e. g. , Massachusetts, San Francisco, Vancouver) and national systems like South Korea's Weight-Based Food Waste Fee. These often require mandatory separate collection systems.

Infrastructure Investment

Governments need to facilitate and invest in the development of adequate collection infrastructure (e. g. , curbside organics bins) and processing capacity (sufficient industrial composting and AD facilities) to handle the diverted materials. Incentives can encourage private sector investment.

Extended Producer Responsibility (EPR)

Implementing EPR schemes holds producers financially or operationally responsible for the end-of-life management of their products, including biodegradable packaging. Funds generated can support collection and processing infrastructure, and the financial incentive can encourage producers to design products for better circularity.

Strategic Policy Signals

Regulations like the EU's Single-Use Plastics Directive (SUPD), which restricts many single-use plastic items including most biodegradable/compostable alternatives, signal a policy prioritization of reduction and reuse over single-use solutions, even biodegradable ones. This influences market direction and innovation focus.

The effectiveness of biodegradable materials is thus heavily shaped by policy choices – from creating the market pull through landfill bans to ensuring clarity through labeling rules and enabling processing through infrastructure investment.

Driving Innovation

Continued innovation is essential across the value chain:

Materials Science

Developing next-generation biodegradable materials with improved performance (e. g. , barrier properties, durability for specific applications) and more reliable, faster degradation profiles in a wider range of real-world environments.

Polyhydroxyalkanoates (PHAs), produced by microbial fermentation, show particular promise for biodegradability in soil and marine environments compared to PLA. Research into novel, sustainable feedstocks, including waste streams and algae, is also crucial.

Processing Technologies

Advancing the efficiency and outputs of composting and AD. This includes optimizing AD through co-digestion, feedstock pre-treatment (thermal, chemical, mechanical hydrolysis), temperature-phased or acid/gas-phased digestion, high-solids AD, and improved digestate treatment for nutrient recovery. Innovations in composting include advanced aeration techniques and in-vessel systems for better control and faster processing.

Sorting and Identification

Developing cost-effective technologies to accurately identify and sort biodegradable/compostable items from mixed waste streams, preventing contamination. Smart labeling technologies (e. g. , digital watermarks, RFID) could potentially link packaging to specific disposal instructions or facilitate automated sorting.

Biological Recycling

Exploring pathways where microorganisms are used to break down polymers (like bioplastics) back into their constituent monomers, which can then be purified and re-polymerized into virgin-quality materials, offering a potentially cleaner alternative to chemical recycling.

Reinforcing the Waste Hierarchy

Crucially, biodegradable solutions must be positioned correctly within the waste hierarchy and the broader CE framework. Efforts to promote biodegradable materials should always be complementary to, and not substitutes for, strategies higher up the hierarchy:

- Reduce: Eliminating unnecessary packaging and materials altogether.

- Reuse: Designing products and systems for multiple uses (e. g. , refillable containers, durable serviceware).

- Recycle: Maintaining and improving systems for recycling conventional materials (like PET, HDPE, metals, glass, paper) where these offer efficient and high-value recovery pathways.

Biodegradation and composting should be reserved for specific, targeted applications where these higher-order strategies are demonstrably less feasible or environmentally beneficial.

The optimal approach for integrating biodegradable materials will inevitably vary depending on local circumstances. Factors such as existing waste management infrastructure, population density, local policies, economic conditions, agricultural needs (for compost/digestate), and public awareness levels all influence the feasibility and effectiveness of different strategies.

Successful programs, like those in San Francisco and South Korea, demonstrate the importance of combining policy mandates with infrastructure development and public engagement tailored to the local context. A one-size-fits-all global solution is unlikely; context-specific planning and implementation are key.

Conclusion

The relationship between biodegradable materials and the circular economy is multifaceted and context-dependent. Naturally biodegradable organic waste, such as food scraps and yard trimmings, is unequivocally a core component of the circular economy's biological cycle. When managed effectively through pathways like composting and anaerobic digestion, these materials are transformed from waste liabilities into valuable resources – nutrient-rich soil amendments and renewable energy – thereby closing resource loops and actively regenerating natural systems.

Ultimately, the successful incorporation of biodegradable materials into a circular future depends on their thoughtful integration into well-designed and efficiently functioning systems. It requires a shift from viewing biodegradability solely as an end-of-life disposal property to understanding it as one potential pathway within a complex, interconnected system aimed at preserving resource value and regenerating natural capital. Only through such a systemic and strategic approach can the promise of biodegradable materials be realized as part of a truly circular economy.