Introduction

The proliferation of packaging waste presents an increasingly urgent global environmental challenge. Landfills are reaching capacity, and the accumulation of non-degradable materials, particularly plastics, pollutes terrestrial and aquatic ecosystems, posing threats to wildlife and potentially human health.

Traditional packaging materials, especially those derived from fossil fuels, can persist in the environment for hundreds of years, exacerbating this problem. In response to these pressing concerns, biodegradable and recyclable packaging have emerged as prominent sustainable alternatives, offering the promise of mitigating the detrimental environmental impacts associated with conventional packaging.

This article aims to provide a comprehensive comparison of these two approaches, delving into their definitions, environmental impacts throughout their lifecycles, the infrastructure required for their management, associated costs, consumer perceptions, and future trends.

By examining these facets, the goal is to elucidate the complexities of each option and offer insights into scenarios where one might be a more suitable choice than the other in the pursuit of a more sustainable future.

Defining Biodegradable and Recyclable Packaging

What is Biodegradable Packaging

Biodegradable packaging is generally defined as any form of packaging that will naturally disintegrate and decompose. This breakdown occurs through the action of naturally occurring microorganisms such as bacteria, fungi, and algae.

The term "biodegradable" has been used broadly for any sustainable packaging material that will naturally break down under any conditions and in an undefined amount of time. This lack of specific timeframes or conditions associated with the term in general highlights a key challenge in assessing the true environmental benefit of materials labeled as biodegradable.

For a clearer understanding of what makes a material biodegradable, including key degradation characteristics and definitions, a more standardized framework is essential.

Unlike the term "compostable," "biodegradable" is not legally regulated, meaning there is no standardized timeframe for degradation, nor is there mandatory testing to ensure the absence of harmful toxins after decomposition. This broad definition can encompass a wide range of materials with varying degradation properties, potentially leading to consumer confusion and concerns about greenwashing.

Despite the lack of a strict universal definition, biodegradable packaging is commonly manufactured using a variety of materials. Plant-based sources are frequently utilized, including cornstarch, derived from the corn or maize plant, which possesses plastic-like characteristics suitable for bottles and loose-film packaging.

Sugarcane, specifically the leftover plant fiber after juice extraction known as bagasse, is another common source, used to create light, waterproof, and food-grade bags and containers that can even be composted at home. Seaweed and algae are also explored for packaging, with agar from these sources being used to create films and cushioning agents; seaweed is considered a highly sustainable raw material.

Mushroom mycelium, the root network of mushrooms, is used to bind together agricultural waste to create strong yet lightweight protective packaging. Hemp, sourced from the cannabis plant, is highly biodegradable, resilient, and versatile, while bamboo, a rapidly growing natural material, is used for various packaging applications. Traditional materials like paper and cardboard remain popular choices due to their inherent biodegradability and recyclability.

Other plant-derived materials like cellulose, PLA (Polylactic Acid) derived from corn starch or sugarcane, starch-based bioplastics, chitosan from crustacean shells, pulp from recycled paper, palm leaves, burlap/jute, organic textiles, coconut shells, eucalyptus, and even avocado are also being utilized or explored for their biodegradable properties. Interestingly, biodegradability is not solely limited to bio-based materials; even some fossil-based polymers, such as PBAT, can be engineered to degrade more quickly than conventional plastics.

The primary characteristic of biodegradable packaging is its ability to break down into natural elements such as water, carbon dioxide, and biomass. The timeframe for this decomposition can vary significantly, ranging from a few days for materials like seaweed films to several months or even years for others, depending on the specific material and the environmental conditions it is exposed to.

In some cases, biodegradable packaging, particularly if it meets specific composting standards, can break down to form nutrient-rich compost, effectively returning valuable resources to the soil. This distinction between simply biodegrading and being compostable is crucial, as compostable packaging offers a more regulated and potentially more beneficial end-of-life scenario.

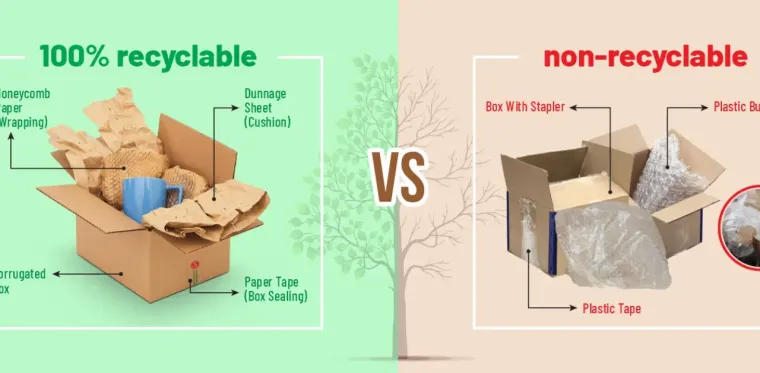

What is Recyclable Packaging

Recyclable packaging, in contrast to biodegradable options, is defined by its ability to be reprocessed and reused to create new products. This process reduces the need for virgin resources and minimizes the amount of waste sent to landfills. The focus is on keeping materials in a circular economy, where they are used, repurposed, and reused for as long as possible.

A wide range of materials are commonly used in recyclable packaging. Paper and cardboard, including corrugated cardboard, paperboard, and kraft paper, are among the most frequently recycled packaging materials. Corrugated cardboard, in particular, stands out for its high recyclability, capable of being recycled as many as 20 times before the fibers become too short for processing.

Various types of plastics, such as Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polypropylene (PP), and sometimes Polystyrene (PS), are also recyclable.

It is important to note that the recyclability of plastics often depends on their resin code, which indicates the type of plastic and its ease of recycling. Glass, especially in the form of bottles, jars, and vials, is another key recyclable material, notable for being infinitely recyclable without any loss in quality.

Metals, including aluminum and steel (often in the form of tinplate), are highly recyclable, with aluminum being particularly efficient to recycle, requiring significantly less energy than producing it from virgin sources. Even wood, commonly used for crates and pallets, can be recycled into mulch or paper pulp.

The fundamental characteristic of recyclable packaging is its ability to be collected, sorted, and reprocessed into new items. Many of these materials can undergo multiple recycling cycles. For instance, paper can be recycled up to six times before its fibers become too short, while aluminum and glass can be recycled infinitely without any degradation in quality.

By enabling the reuse of materials, recyclable packaging plays a crucial role in contributing to a circular economy, diverting valuable resources from landfills and reducing the demand for environmentally intensive virgin material extraction.

Key Differences and Overlapping Concepts

While both biodegradable and recyclable packaging aim to reduce environmental impact, they operate on different principles. Compostable packaging represents a subset of biodegradable materials that are specifically designed to break down into nutrient-rich compost under a defined set of conditions and within a specific timeframe.

These materials must meet stringent standards, such as ASTM D6400 in the US or EN 13432 in Europe, which require them to biodegrade and disintegrate within a specific period in an industrial composting environment, leaving no harmful residues. It is crucial to understand that while all compostable materials are biodegradable, not all biodegradable materials are compostable, as the latter requires more specific conditions and results in a beneficial end product.

The terms "degradable" and "oxo-degradable" often appear in discussions about sustainable packaging. "Degradable" is a broad term that technically applies to anything that breaks down, but it lacks specific standards regarding the process, timeframe, or resulting byproducts. "Oxo-degradable" packaging refers to conventional plastic treated with an additive to accelerate its breakdown through oxidation when exposed to sunlight, heat, or mechanical stress.

However, this process often results in the fragmentation of the plastic into microplastics, which can be harmful to the environment. Therefore, oxo-degradable plastics are generally not considered a sustainable solution and can even be detrimental due to the microplastic pollution they generate.

Interestingly, some materials possess characteristics of both biodegradability and recyclability, or biodegradability and compostability. For example, paper and cardboard are inherently biodegradable and are also widely recycled.

Similarly, certain bioplastics derived from renewable resources can be designed to be both biodegradable and compostable, offering multiple sustainable end-of-life options depending on the available infrastructure and specific material composition.

This overlap highlights the complexity of choosing the most environmentally sound packaging solution and underscores the importance of considering the specific properties of the material and the intended disposal method.

The Environmental Footprint of Biodegradable Packaging

Production Processes and Resource Consumption

The environmental impact of biodegradable packaging begins with the sourcing of its raw materials. Many biodegradable materials are derived from plant-based sources such as corn, sugarcane, seaweed, hemp, and bamboo.

While these resources are often renewable, their cultivation can raise concerns regarding land use, deforestation, water consumption, the use of pesticides and fertilizers, and the potential for competition with food production. For instance, the production of PLA from corn can be particularly water-intensive.

Typical industrial agriculture practices associated with these crops, such as extensive fertilization and pesticide utilization, can be detrimental to soil health and surrounding ecosystems. Therefore, the sustainability of biodegradable packaging relies heavily on the adoption of sustainable farming practices to minimize these negative impacts.

The energy consumption associated with the production of biodegradable packaging is another critical factor in assessing its environmental footprint. While it is often asserted that biodegradable materials require less energy to produce compared to conventional plastics, this is not always the case and can vary significantly depending on the specific type of biodegradable material and the manufacturing processes involved.

Some studies indicate that certain biodegradable materials, such as PLA and PHA, can have lower greenhouse gas emissions throughout their life cycle compared to traditional petroleum-based plastics.

However, the energy intensity of manufacturing these materials can still be substantial, often relying on fossil fuels. To truly minimize the carbon footprint of biodegradable packaging, it is essential to transition to the use of renewable energy sources in the manufacturing processes.

Furthermore, the production of certain biodegradable materials can be quite water-intensive. For example, the water footprint of corn, a common feedstock for PLA, is estimated to be significant. This high water consumption can be a major environmental drawback, particularly in regions facing water scarcity, and highlights the importance of considering the overall resource demands associated with biodegradable packaging production.

A comprehensive life cycle assessment, which evaluates the environmental impact at every stage from raw material extraction to disposal, is crucial for accurately comparing the environmental footprint of biodegradable packaging with other options.

The Decomposition Journey

The environmental benefits of biodegradable packaging are contingent upon its ability to decompose effectively. However, the conditions required for biodegradation vary considerably depending on the specific material. Many biodegradable plastics necessitate the controlled environment of industrial composting facilities, where specific temperatures and humidity levels are maintained to facilitate rapid breakdown.

Proper disposal is essential to ensure these materials break down as intended and don’t end up persisting in landfills.

These conditions may not be readily available in all regions, limiting the effectiveness of these materials if they end up in landfills or natural environments. In contrast, some biodegradable packaging, particularly those made from simpler plant-based materials like paper, seaweed, or bagasse, may be capable of degrading in home composting systems or even in natural environments such as soil and water.

The timeframe for decomposition also varies widely. While some materials, like seaweed films, can break down within days, others may take several months or even years to fully degrade. It is important to reiterate that the term "biodegradable" itself does not specify a required timeframe for decomposition, which can be misleading.

Studies have even shown that some plastic bags marketed as "biodegradable" can persist in soil and seawater for years, questioning their effectiveness in reducing litter and marine pollution compared to conventional plastics.

Ideally, the byproducts of biodegradable packaging decomposition should be benign, consisting of water, carbon dioxide, and biomass, potentially enriching the soil with nutrients, especially in the case of compostable materials.

However, concerns have been raised about the potential for some biodegradable plastics to fragment into microplastics during the degradation process. These tiny plastic particles can persist in the environment, potentially entering the food chain and posing risks to ecosystems and human health.

Potential for Soil and Water Contamination

Beyond the issue of microplastics, some biodegradable packaging may contain additives or break down into substances that can leach into the soil and water, leading to contamination. These substances can disrupt microbial communities, nutrient cycles, and potentially harm aquatic life and human health.

A particular concern involves the use of per- and polyfluoroalkyl substances (PFAS) in some compostable food packaging to provide greaseproof and waterproof coatings. PFAS are known as "forever chemicals" due to their persistence in the environment and have been linked to various health problems. These chemicals can leach from the packaging into food, soil, and groundwater, accumulating in animals, people, and plants.

Furthermore, biodegradable plastics that do not fully break down in composting environments or that contain harmful substances can contaminate the resulting compost, reducing its value as a soil amendment. Compost contamination occurs when non-compostable items or residues from packaging that doesn't meet composting standards get mixed into the compost pile.

This can introduce microplastics or harmful chemicals into the compost, negating the intended environmental benefits of composting. Therefore, the composition of biodegradable packaging and its proper disposal are critical factors in preventing soil and water contamination.

The Environmental Footprint of Recyclable Packaging

Production Processes

The production of recyclable packaging, while generally considered more environmentally friendly than using only virgin materials, still often requires the input of virgin resources.

For example, the production of paper-based packaging necessitates wood pulp, and the manufacturing of plastic and glass packaging typically involves raw materials derived from fossil fuels and natural minerals, respectively. However, a key advantage of recyclable packaging is the potential to incorporate significant amounts of post-consumer recycled (PCR) content.

Utilizing recycled materials reduces the demand for virgin resources, conserves energy, lowers greenhouse gas emissions, and decreases the amount of waste sent to landfills. Many recyclable materials, such as paperboard, plastics, and aluminum, can be produced with substantial proportions of recycled content.

Recycling processes generally require less energy compared to the production of packaging from virgin materials. For instance, recycling aluminum is particularly energy-efficient, saving a significant amount of energy compared to producing primary aluminum.

Similarly, recycling glass melts at a lower temperature than its raw materials, resulting in energy savings. However, the energy intensity of recycling can vary depending on the type of material and the specific recycling technologies employed.

Water is also consumed in recycling processes, although often in smaller quantities compared to the production of packaging from virgin resources. For example, the paper recycling process involves pulping the paper with water to separate the fibers.

Overall, the incorporation of recycled content in recyclable packaging offers substantial environmental benefits by reducing the strain on natural resources, lowering energy consumption, and minimizing waste generation.

The Recycling Process

The effectiveness of recyclable packaging is intrinsically linked to the efficiency and reach of the recycling infrastructure. The recycling process typically involves several key steps, beginning with collection. Efficient collection systems are crucial for capturing recyclable materials and preventing them from ending up in landfills.

These systems can include curbside collection programs for households, deposit return schemes for beverage containers, and business-to-business collection services. The accessibility and convenience of these programs significantly influence public participation and the overall success of recycling efforts. However, the availability and sophistication of recycling programs can vary considerably across different regions and countries.

Once collected, recyclable materials are transported to Materials Recovery Facilities (MRFs) where they undergo sorting. This stage involves separating the mixed recyclables into different material types, such as paper, plastic, glass, and metal.

Sorting can be a complex process, often involving a combination of manual labor and automated technologies like optical scanners and magnets. The efficiency of sorting is critical for ensuring that each material stream is clean and can be effectively reprocessed.

After sorting, the separated materials are processed into forms that can be used to manufacture new products. For example, paper and cardboard are pulped and then formed into new paper products. Plastics are typically shredded, melted, and then pelletized for use in new plastic products. Glass is crushed and melted down to create new glass containers.

Metals are also melted and reformed into new metal items. Each of these processing stages requires energy for transportation, sorting, and the actual reprocessing of the materials.

While the overall energy consumption of recycling is generally lower than that of virgin production, the energy requirements of each step should be considered when evaluating the environmental benefits. Ideally, the energy used in the recycling process should increasingly come from renewable sources to further minimize the environmental impact.

Challenges of Contamination and Material Degradation

Despite the inherent benefits of recycling, several challenges can limit its effectiveness. Contamination of recyclable materials with non-recyclable items or food residue is a significant issue.

Contaminants can reduce the quality of the recycled materials or even render entire batches unrecyclable, leading to their disposal in landfills. Proper cleaning of recyclables by consumers and accurate sorting at MRFs are essential to mitigate this problem. Additionally, packaging made from multiple different materials can be challenging to separate during the recycling process, reducing its recyclability.

Another challenge is the material degradation that can occur with each recycling cycle, particularly for plastics. Unlike materials like glass and aluminum, which can be recycled repeatedly without losing quality, some plastics degrade in strength and performance over time.

This degradation often necessitates the addition of virgin materials to maintain the quality of the recycled plastic. In some cases, recycled plastics may only be suitable for "downcycling," where they are used to create products of lower quality than the original packaging.

Finally, the design of packaging, including the use of labels, adhesives, and inks, can also impact its recyclability. Certain types of labels or adhesives may be difficult to remove during the recycling process, potentially contaminating the recycled material. For example, vinyl labels and shrink-wrap sleeves on aluminum cans can cause contamination.

Metallic inks used in printing can also pose challenges for paper recycling. Opting for wash-off adhesives for materials like glass and PET bottles can improve their recyclability. Designing packaging with these considerations in mind is crucial for enhancing the overall recyclability of packaging materials.

Global Infrastructure for Handling Packaging Waste

Composting Facilities for Biodegradable Materials

The effective management of biodegradable packaging, particularly biodegradable plastics, often relies on the availability of appropriate composting infrastructure. Many biodegradable plastics require the specific conditions found in industrial composting facilities to achieve proper decomposition.

These facilities maintain higher temperatures and controlled humidity levels, which are necessary for the efficient breakdown of these materials. However, the availability and capacity of industrial composting facilities vary significantly across different regions and countries.

In many areas, this infrastructure is limited or non-existent, posing a significant barrier to the proper disposal of many biodegradable plastics. Without access to these specialized facilities, biodegradable plastics may end up in landfills, where they may not break down as intended and could even contribute to methane emissions, a potent greenhouse gas.

Some types of biodegradable packaging, especially those made from simpler plant-based materials like paper, cardboard, bagasse, or seaweed, can be composted in home composting systems. However, the success of home composting depends on consumer participation and knowledge of proper composting practices.

Developing adequate composting infrastructure faces several challenges. The cost of building and operating these facilities can be substantial. Additionally, establishing efficient collection and sorting systems for compostable waste is necessary to ensure that only appropriate materials are processed and that the resulting compost is free of contaminants like conventional plastics.

Despite these challenges, some regions have made significant progress in developing composting infrastructure. For example, Italy has widely supported and used certified compostable packaging, achieving a high separate collection rate of household food waste. This demonstrates that with the right policies and investments, robust composting systems for biodegradable packaging can be established.

Recycling Systems for Various Materials

In contrast to composting, recycling infrastructure for various packaging materials is more established globally, although its reach and effectiveness still vary considerably depending on the material type and geographic location.

Paper and cardboard recycling systems are generally well-developed in many parts of the world, with relatively high recycling rates. Corrugated cardboard, being a common and easily recyclable material, often has particularly high recovery rates.

Plastic recycling infrastructure is more complex and varies significantly based on the specific type of plastic, identified by its resin code. While many types of plastics are technically recyclable, the actual recycling rates for plastics are generally lower than those for paper or metals. This is due to factors such as difficulties in sorting different types of plastics, contamination issues, and the economic viability of recycling certain plastic resins.

Glass recycling is also well-established in many regions, with the significant advantage that glass can be recycled infinitely without any degradation in quality, making it a highly valuable material in a circular economy. Metal recycling, particularly for aluminum and steel, is highly effective and boasts high recycling rates. Recycling aluminum is especially beneficial due to the substantial energy savings compared to primary production.

Despite the existence of recycling infrastructure for these materials, several challenges persist globally. There is a lack of standardization in recycling systems across different regions and countries, making it difficult for consumers and businesses to navigate recycling guidelines consistently. Inadequate collection and sorting systems in some areas lead to lower recycling rates and higher levels of contamination.

Additionally, the economic viability of recycling certain materials can fluctuate based on market conditions and the quality of the collected materials. Addressing these challenges through improved infrastructure, standardized practices, and economic incentives is crucial for maximizing the benefits of recyclable packaging on a global scale.

Economic Considerations

Cost Comparison of Producing Biodegradable vs. Recyclable Packaging

The economic feasibility of biodegradable and recyclable packaging is a significant factor influencing their adoption. The production costs of biodegradable packaging can sometimes be higher than those of conventional plastics.

This can be attributed to factors such as the sourcing of raw materials, which may involve specialized agricultural practices or emerging bio-based feedstocks, as well as the processing technologies required for their conversion into packaging materials. Lower production volumes for some biodegradable materials compared to conventional plastics can also contribute to higher unit costs.

However, some sources suggest that biodegradable packaging can lead to potential cost savings through the use of more readily available and affordable raw materials, such as cornstarch, or through the reduction in the amount of material needed due to innovative designs.

The production costs of recyclable packaging can vary depending on the specific material being used and the proportion of recycled content incorporated. Utilizing recycled materials can sometimes be more cost-effective than using virgin resources in the long run, particularly when considering the environmental benefits and potential savings in waste disposal costs.

For example, recycling aluminum requires significantly less energy than producing it from bauxite ore, which can translate into cost advantages. However, the cost of recycled materials can fluctuate based on market demand and the availability of collected recyclables.

Market fluctuations and economies of scale can influence the costs of both biodegradable and recyclable packaging. As the demand for sustainable packaging options continues to grow, increased production volumes for biodegradable materials could potentially lead to lower manufacturing costs due to economies of scale and advancements in production technologies.

Similarly, investments in recycling infrastructure and improved collection and sorting efficiencies could further enhance the economic competitiveness of recyclable packaging.

Costs Associated with Disposal and Waste Management

The costs associated with the disposal and waste management of biodegradable and recyclable packaging also play a crucial role in their overall economic viability. If biodegradable packaging is properly composted, it can divert waste from landfills, potentially reducing landfill disposal fees.

In some cases, the compost produced can even be sold, generating revenue. However, if biodegradable packaging is not composted due to lack of infrastructure or improper disposal, it may end up in landfills, where it could contribute to methane emissions, and the anticipated economic and environmental benefits would not be realized.

Recycling can also lead to cost savings in waste management by reducing the volume of waste sent to landfills. Furthermore, the recovered recyclable materials can be sold to manufacturers, generating revenue that can offset the costs of the recycling programs. However, contamination of recyclable materials can increase the costs of processing and reduce the value of the recovered materials, potentially impacting the economic viability of recycling programs.

Extended Producer Responsibility (EPR) schemes are increasingly being implemented around the world. These policies make producers responsible for the end-of-life management of their packaging, which can significantly influence the overall costs and incentivize the use of more sustainable packaging options, including both biodegradable and recyclable materials.

By shifting the responsibility for waste management to producers, EPR schemes can encourage the design of packaging that is easier and more cost-effective to recycle or compost, ultimately contributing to a more circular and sustainable economy.

Consumer Perceptions and Behaviors

Understanding and Awareness of Different Packaging Types

Consumer awareness of environmental issues and the demand for more sustainable products have been steadily growing. This increasing environmental consciousness has led many consumers to seek out and even be willing to pay a premium for products packaged in materials that are perceived as being better for the planet. Both biodegradable and recyclable packaging are often viewed favorably by consumers as alternatives to traditional, less sustainable options.

However, despite this growing interest, confusion and misconceptions about the terms "biodegradable," "compostable," and "recyclable" are common among consumers. The lack of clear and consistent definitions and labeling can lead to misunderstandings about how these different types of packaging should be disposed of and their actual environmental benefits.

For more on common myths and misconceptions around degradable products, see debunking myths about biodegradable trash.

For example, consumers may mistakenly believe that all biodegradable packaging will readily break down in any environment, including landfills or as litter, which is often not the case. Similarly, the distinction between biodegradable and compostable packaging is not always well understood, leading to improper disposal in recycling bins or landfills.

The lack of clear labeling and disposal instructions on packaging further exacerbates this issue, making it difficult for consumers to make informed choices and dispose of packaging correctly. Without clear guidance, consumers may inadvertently contaminate recycling streams with compostable or biodegradable items, or vice versa, undermining the intended environmental outcomes.

Acceptance and Willingness to Adopt Sustainable Packaging

Despite the existing confusion, consumer acceptance of sustainable packaging, including both biodegradable and recyclable options, is generally high. Consumers are increasingly seeking out products that are packaged in an environmentally responsible manner, and the use of such packaging can enhance a brand's image and foster greater customer loyalty.

Many consumers are even willing to pay a premium for products that come in sustainable packaging, indicating a strong market demand for these alternatives.

However, convenience and ease of disposal remain important factors for consumer acceptance. If sustainable packaging options are perceived as being too difficult to handle or dispose of properly, consumers may be less likely to embrace them. Therefore, it is crucial that biodegradable and recyclable packaging are not only environmentally sound but also convenient for consumers to use and manage at the end of their life cycle.

Confusion and Misconceptions

Addressing the existing confusion and misconceptions surrounding biodegradable and recyclable packaging is essential for maximizing their environmental benefits.

Clear and consistent labeling that includes explicit disposal instructions and relevant certifications, such as logos indicating compostability according to recognized standards, is paramount. For example, packaging certified as compostable should clearly display a certification logo and state "compostable" to avoid ambiguity.

Public education campaigns play a vital role in raising consumer awareness about the different types of sustainable packaging, their proper disposal methods, and the environmental implications of each option.

These campaigns can help consumers understand the nuances between biodegradable, compostable, and recyclable packaging and guide them on how to correctly sort and dispose of these materials in their local waste management systems.

Furthermore, it is crucial to combat "greenwashing," where products are marketed as environmentally friendly without sufficient evidence or with misleading claims. Regulatory oversight and clear standards for environmental claims on packaging can help ensure that consumers are provided with accurate and reliable information, enabling them to make truly sustainable choices.

By addressing consumer confusion and ensuring transparency, the effectiveness of both biodegradable and recyclable packaging in contributing to a more sustainable future can be significantly enhanced.

Innovations and the Future of Packaging

Emerging Materials and Technologies in Biodegradable Packaging

The field of biodegradable packaging is characterized by ongoing innovation in the development of new materials and technologies. Researchers and companies are continuously exploring novel bio-based polymers with enhanced performance characteristics and improved biodegradability across various environments.

One particularly interesting area is the development of edible packaging films and containers made from natural ingredients, which can be consumed along with the food, eliminating packaging waste altogether.

Another promising trend is the increasing utilization of agricultural waste and byproducts, such as bagasse, straw, and hemp, as raw materials for biodegradable packaging. This approach not only provides a sustainable alternative to virgin resources but also helps to valorize waste streams.

Innovations are also focused on enhancing the barrier properties of compostable packaging to make them suitable for a wider range of food packaging applications, ensuring the freshness and integrity of the contents.

Furthermore, research is being conducted on biodegradable packaging that can dissolve in water or even seawater, offering a potential solution to plastic pollution in marine environments.

Innovative material blends that combine biodegradable plastics with natural fibers or recycled materials are also being explored to enhance strength and reduce the overall environmental impact. Finally, emerging technologies like 3D printing are being investigated for their potential to create customized packaging with minimal waste, further contributing to sustainability efforts.

Advancements and Trends in Recyclable Packaging Solutions

The future of recyclable packaging is also marked by significant advancements and evolving trends. A key focus is on the development of easily recyclable mono-material packaging to overcome the challenges associated with multi-layer packaging, which can be difficult to separate and recycle.

Increasing the use of post-consumer recycled (PCR) content in packaging remains a crucial trend, driving demand for high-quality recycled materials and reducing reliance on virgin resources.

Improved recycling technologies, particularly for plastics, are being developed, including chemical recycling processes that can break down plastics into their constituent monomers, allowing for the creation of new, high-quality plastics and addressing the issue of material degradation.

The principle of "design for recyclability" is gaining prominence, emphasizing the creation of packaging that is inherently easier to collect, sort, and reprocess. This includes avoiding problematic labels, adhesives, and additives that can hinder the recycling process.

The concept of smart packaging is also emerging, with features that can aid in sorting at recycling facilities or provide consumers with information about how to properly recycle the packaging.

Finally, there is a growing emphasis on reusable and returnable packaging systems, which aim to reduce the need for single-use packaging altogether by encouraging consumers to return packaging for cleaning and refilling. These systems represent a significant shift towards a more circular approach to packaging consumption.

Advantages and Disadvantages

Pros and Cons of Biodegradable Packaging

| Pros | Cons |

|---|---|

| Potential to reduce plastic pollution and landfill waste | Biodegradation often requires specific industrial composting conditions not widely available |

| Can be made from renewable resources | Can contribute to microplastic pollution in some cases |

| Some types are compostable, returning nutrients to the soil | Potential for soil and water contamination from additives or breakdown products |

| Can enhance brand image and appeal to environmentally conscious consumers | Can contaminate recycling streams if mixed with recyclable materials |

| May require less energy to produce in some cases | Production can be resource-intensive (water, land) and may compete with food production |

| Can be more expensive to produce than conventional plastics in some instances | |

| Consumer confusion and improper disposal are common |

Pros and Cons of Recyclable Packaging

| Pros | Cons |

|---|---|

| Reduces the need for virgin resources | Recycling processes still require energy and can have environmental impacts |

| Can significantly reduce landfill waste | Material degradation can occur with each recycling cycle, limiting reuses |

| Generally requires less energy for production than virgin materials | Contamination can hinder the recycling process and reduce quality |

| Established infrastructure exists for many materials in many regions | Not all materials are easily or widely recycled (e.g., certain plastics) |

| Contributes to a circular economy | Can still generate waste if recycling rates are low or materials are not properly sorted |

| Can be cost-effective, especially with recycled content | The quality of recycled materials may not always meet all packaging needs |

When to Choose Which

Situations Favoring Biodegradable Packaging

Biodegradable packaging may be a more suitable choice in specific scenarios. For food packaging where contamination with food waste is likely, and composting is a viable disposal method, biodegradable and especially compostable options can be advantageous.

For example, compostable take-out containers can be composted along with food scraps, reducing contamination of other waste streams and potentially creating valuable compost. In applications where packaging might foreseeably end up in natural environments, such as agricultural mulch films designed to biodegrade in soil, biodegradable options can minimize long-term environmental harm.

In closed-loop systems where compostable packaging is specifically collected and processed in dedicated composting facilities, the benefits of biodegradation and compost production can be fully realized. Additionally, for products with a short shelf life where the packaging lifespan aligns with the biodegradation timeframe, biodegradable options can be effective.

Situations Favoring Recyclable Packaging

Recyclable packaging is often a better choice for materials that have well-established and effective recycling infrastructure, such as aluminum cans, glass bottles, and corrugated cardboard. These materials can be efficiently collected, sorted, and reprocessed into new products, conserving resources and reducing waste.

For products that require strong barrier properties or durability that some biodegradable materials may not yet adequately provide, recyclable options like certain plastics or metals might be more suitable.

Packaging for products that are likely to be kept clean and dry by consumers, such as many consumer goods, increases the likelihood of successful recycling, making recyclable packaging a favorable choice. Furthermore, for reusable packaging systems where durability and the ability to withstand multiple uses are key, recyclable materials that are robust and can be effectively cleaned and reused are often preferred.

Conclusion

In conclusion, the analysis reveals that there is no universally "better" option between biodegradable and recyclable packaging. The optimal choice is highly context-dependent, influenced by a complex interplay of factors. Ultimately, both biodegradable and recyclable packaging hold significant potential to contribute to a greener future when implemented thoughtfully and effectively.

They should be viewed as complementary tools within a broader strategy aimed at reducing packaging waste, conserving resources, and minimizing environmental impact. The most sustainable path forward will likely involve a tailored approach, carefully considering the specific context and leveraging the strengths of each option to create a more circular and environmentally responsible packaging landscape.